The effective implementation of construction planning and materials management throughout the project

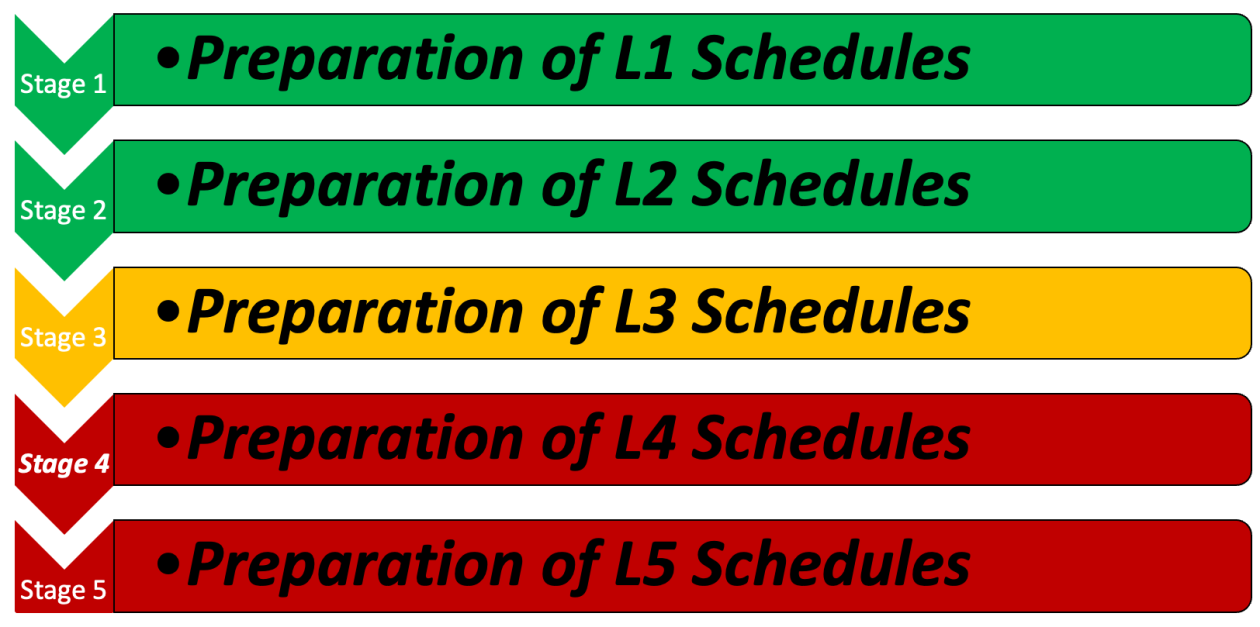

Planning and monitoring are one of the main components of any project. After all, we know that planning is the "backbone" of projects. If we can prepare and implement a proper schedule and adequate monitoring of progress, then we can also master the project. There are different types of schedules used in projects for better understanding and monitoring. The project schedules that I have generally used in my projects are L1 schedules, L2 schedules, L3 schedules, L4 schedules and L5 micro-resource schedules. L5 micro-resource schedules are detailed and microscopic schedules. In other words, this is detailed micro scheduling for bottom-level monitoring. One of the main tasks I faced in my projects was the risk analysis of the schedule. This is because, usually, hardly anything works out exactly as planned. Every project has different types of risks that can have a negative impact on the ongoing project and to mitigate or prevent risks entirely, we need to be able to analyse them. An important tool for analysing the risk is PERT Master (Primavera Risk Analyzer).

There are two types of risk mitigation plans that are usually used in a project: 'pre-mitigation plans' and 'post-mitigation plans'. In the following text these plans related to construction projects will be discussed. As the title suggests, I will not only talk about the effective implementation of construction planning, but also about another important part of a construction project: materials management. You will learn more about this in the second part of my article.

Level of schedules: Project schedules and their implementation

Schedules play an essential role in a project. Depending on the nature of the project, we can develop five types of schedules: L1, L2, L3, L4 and L5, which represent the detailed division of tasks. In these plans we can divide the activities into several time periods. From L4 we can use the technique of integrated scheduling. L5 is a detailed micro-planning of the projects, which allows us to monitor information at the bottom-level and improve resource planning and management. We can also divide the work force by blocks and groups. We can create all the above plans using Primavera or MS Project.

Project plans

At the site level, we can implement the different types of planning for site activities and tracking of site progress. Once the plans are in place, we can easily monitor the delays in activities while preparing the catch-up plans and further mitigation.

Construction plans

Construction plans

- Preparation of monthly look ahead plans (one and two months look ahead)

- Preparation of weekly look ahead plans

- Preparation of daily planning

Project risk analysis

To ensure the successful completion of the project, it is of utmost importance for the person planning to find ways to deal with project uncertainties that may pose a potential risk to a project. We know that risk can relate to any aspect of the project. In order to complete or move the project forward on schedule, the only way is to identify the risk and develop a plan to address it. Remember that project risk analysis is an iterative task!

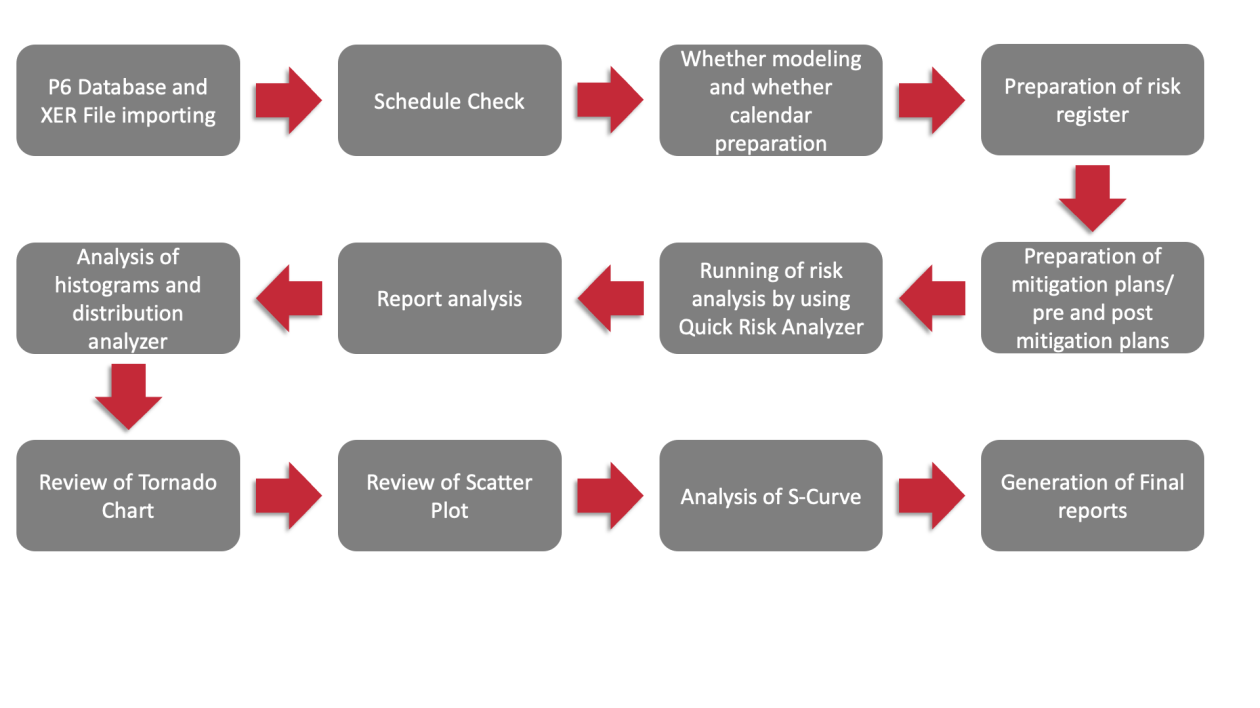

To identify project risks, we can use the Primavera P6 Risk Analysis (PERT Master). This allows us to monitor and identify the performance of schedule and cost risk analysis, and we can track and manage both qualitative and quantitative project risks and their impacts and response plans.

The main features of the Primavera Risk Analysis (PERT Master) are

To identify project risks, we can use the Primavera P6 Risk Analysis (PERT Master). This allows us to monitor and identify the performance of schedule and cost risk analysis, and we can track and manage both qualitative and quantitative project risks and their impacts and response plans.

The main features of the Primavera Risk Analysis (PERT Master) are

- Schedule check

- Templated quick risk

- Risk register wizard

- Risk register (quantitative & qualitative)

- Risk analysis

- Development of a risk model

- Reviewing the results

- Creation of reports/charts

Steps of the risk analysis - flow chart

PERT Master and Monte Carlo Analysis

The risk analysis of PERT Master/Oracle Primavera is usually based on the principle and philosophy of "Monte Carlo analysis". With the help of Monte Carlo analysis, it is possible to monitor several potential project completion dates and the most probable budget required for the project. Using Monte Carlo analysis, we can derive the probability curve for each task in the schedule. Another important point is that with this technique we can analyse whether the project is running within the planned cost or not, and with the help of iteration processes, curves and diagrams we can determine the probability of the project being completed.

Project Mitigation plans

By using risk mitigation plans, we can reduce the risk and delays in the schedules and increase the likelihood of final project completion within the pre-established timeframe. Generally, there are two types of mitigation plans used in a project:

With the help of mitigation plans, we can categorise the respective risk into different levels depending on the score we have received:

- Pre mitigation plans

- Post mitigation plans

With the help of mitigation plans, we can categorise the respective risk into different levels depending on the score we have received:

- High risk > 23

- Medium risk >5

- Low risk <=5After analysing the assessment result, we can reduce the risk level by using post mitigation plans.

Material Monitoring and look ahead plans

As we know, material management is one of the most important parts of the project, so material management plays a key role in the successful completion of the project. Prior to any project, it is necessary to determine what the minimum WBS requirements are at the beginning of the project. So it is the main task of a planner to identify the minimum WBS requirements of the site, and the same must be communicated to the project and procurement teams for the flow of materials. Another important point in materials management is to prepare look ahead plans in relation to the progress and condition of the site. We can implement the following key points on the construction site with the preparation of look ahead material plans (in general, we can implement a 15-day material requirement plan, a one-month look ahead plan and a two-month advance plan):

- Tracking of the material flow

- Preparation of material delay reports

- Timely reporting to the project managers

- Maintaining a material receipt and issue register using SAP or MS Excel

- Preparation of reports on actual material compared to planned material

- Proper material reconciliation

Value of Project Review Team (PRT) meetings

We can hold project meetings on a regular base (e.g. video calls at the end of the month). In the PRT meetings we can jointly discuss the project progress and the objectives and requirements of the coming month, as well as the main risks of the projects. We can hold mid-PRT meetings at the site level every 15 days to prepare for the monthly PRT meeting. We can also introduce the presence of staff from all departments of the projects.

Important preparations we should do on site for PRT meetings:

Important preparations we should do on site for PRT meetings:

- Preparation of the project status at the current time

- Preparation of target plans for the next month

- Preparation of material look ahead plans and material plan/actual report with detailed delay

- Preparation of the meeting schedule for the next month

Conclusion

There are many risks that can occur during a project and jeopardise the project. But we are not left penniless. If we can use a great project review team with the latest software and technologies, we can reduce project risk, and by implementing detailed schedules and updating schedules according to project progress, we will be able to achieve project completion within time.

Author: Mahesh EV is a project manager with more than 11 years of practical experience and the Senior Official of the IAPM in the metropolitan regions of New Delhi, Trivandrum and Calicut, India. Mahesh's implementation of many procurement and construction projects has broadened his experience. He has demonstrated his skills in the successful planning and execution of several projects, such as thermal power plants and renewable energy projects across India – from kick-off to handover of the plant.

Key words: Project management, Material Management, Construction planning, Tip